Single Table | Exchange Table| Plate-tube |Tube

1000W/1500W/2000W/3000W/4000W/6000W/8000W/10000W/12000W

Fiber Laser Cutting Machine use 20mm thickness plate to weld body. More stable .With high precision and high speed.Top brand machine parts. More than 10years of production experience.Professional sales and after-service team. 24X7 service.

I、Product Introduction

YAHONG TECHNOLOGY CO.,LTD is a professional manufacturer of laser cutting machine.Our product include single table laser cutting machine,Full cover laser cutting machine, exchange table laser cutting machine, Tube laser cutting machine ,having 500W / 700W / 1000W / 1500W / 2000W / 3000W / 4000W / 6000W/8000W/10000W/12000W etc。Our products are sold all over the country and are sold to Europe, America, Southeast Asia and other dozens of countries and regions.

II.Parameters

Environment

III.laser cutter Main features:

1、The photoelectric conversion efficiency can reach 30%, twice that of CO2;

2、Less power consumption, CO2 is 20% ~ 30%;

3、No laser work gas, can save a lot of laser maintenance cost;

4、Optical fiber transmission, without reflection lens, do not need to adjust the light path.

5、Used forcutting non-ferrous metals, aluminum alloy, copper and other materials

IV.Fiber laser cutting machine features:

1.Gantry double drive structure, smooth and reliable movement;

2.Independent research and development design, the manufacture of machine tool bed, special processing technology, high precision of machine tool, stable and reliable, long life;

3.Precision gear rack drive, with high precision gear reducer, high response and high precision servo motor;

4.The international first-class quality of fiber laser, industrial application for many years, long service life, maintenance free, stable and reliable;

5.High precision laser cutting head, imported optical lenses, is focused on the fine, the adjustment is convenient, cutting perfect;

6.A double closed-loop control capacitiver torch height controller, low requirement to the steel plate, cutting quality is stable and reliable;

7.CNC system is simple and easy operation, low requirements for the operator;

8.Cutting graphic input multiple formats, powerful draw and edit graphics function;

9.Special cutting software, cutting technology experts, data call functions;

10.Automatic refueling system;

11.Cutting gas pressure proportional valve to adjust automatically,not need manual adjustment;

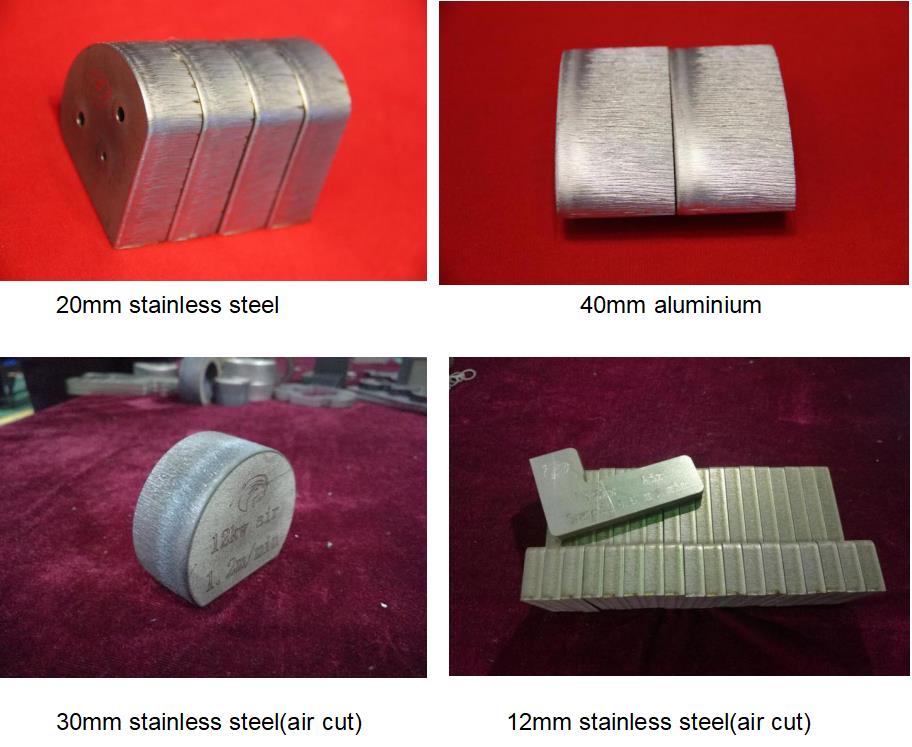

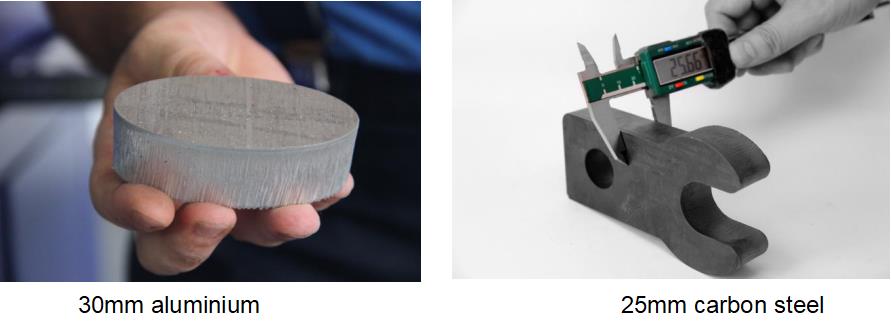

VI.laser cutting machine cutting samples:

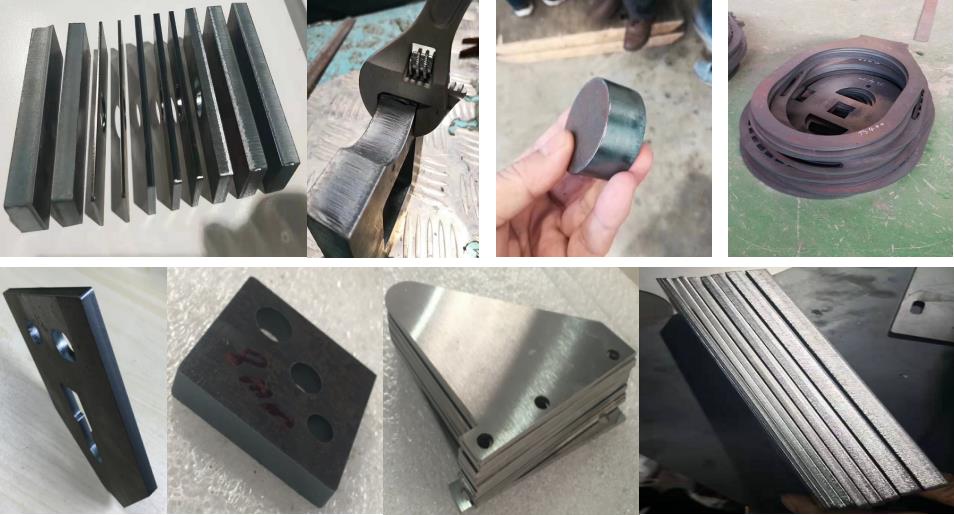

VII.Fiber laser machine body process photos:

Our bed is designed very reasonable ,strong and stable. We have added longitudinal stiffeners to ensure that the bed does not distort during long-term operationt. It made of 20mm thick high-quality steel(We use marine steel plateCCSB ,its features: good toughness, high strength, good corrosion resistance, good welding performance, processing and molding performance and surface quality) by bending and welding the steel plate. After welding, the stress is removed by one-time quenching. After natural cooling, the rough machining is performed, then the stress is removed by two-time quenching, and after natural cooling, the finishing is performed. The equipment within 13m is integral type, and the upper gantry milling machine is processed once.

Body advantage: it is more strong and stable. Using long time, it is also have high accuracy and ensure cutting accuracy.

Component inspection:

Every component is strictly inspected. After passing the inspection, we can put it into the warehouse for assembly. Non-conforming parts, we return and redo.So we can ensure our machine quality.

Fiber laser cutting machine Package and delivery

Our Certificates:

VIII. Get In Touch With Us To Get:

* 24*7 Service Team!

* Cost-effective price from a manufacturer.

* 24 months warranty for free.

* OEM for you.

What are you waitting for? Contact Me,Get a Free Quote!